OnRobot Debuts Two Electrical Grippers for High-Payload Applications

OnRobot’s new electrical grippers are launching along with the new machine tending solution – AutoPilot – powered by D:PLOY and developed in collaboration with Ellison Technologies.

May 4, 2024

At a Glance

- Here are some stronger grippers for heavier lifting.

- These grippers are designed to handle variable shapes and weights.

- OnRobot collaborated with Ellison Technologies on the new AutoPilot.

Cobot applications have expanded significantly in recent years. These robots are now capable of handling up to 66.13 lb. At the same time, industrial robots are increasingly being deployed in collaborative applications, requiring a stronger end-effector platform that enables improved workpiece adaptability.

To support this, OnRobot has introduced a three-fingered 3FG25 gripper that provides users with 55.1 lb. of payload power in a compact, all electric, lightweight form. “As cobots grow more powerful, OnRobot customers are scaling up their collaborative applications,” said Enrico Iversen, CEO of OnRobot. “Building on the success of our existing, industry-proven gripper range, the new 3FG25 and 2FG14 grippers deliver gripping and payload power while also providing customizability for heavy-duty applications, including harsh environments.”

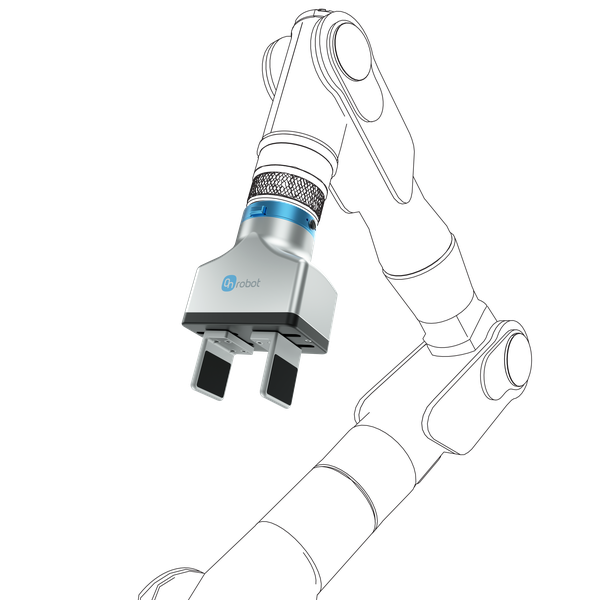

Image courtesy of OnRobot.

The two new grippers provide an intelligent alternative to less adaptable pneumatic systems. They offer an all-round plug and produce experience, including fingers with multiple configurations, flange adapters, cabling and comprehensive software that removes the complexity of robot programming. Increased ability to handle cylindrical workpieces CNC machine tending applications typically involve heavy metal workpieces.

It’s a domain where OnRobot’s 3FG15 has been widely adopted, not least for its ability to successfully handle cylindrical and odd-shaped items. Yet handling heavier parts requires higher forces, and handling bigger parts requires a finger platform designed to accommodate larger custom fingers. The new 3FG25 gripper addresses both requirements, while still being fully electric, and easy to use.

A Stronger Version of a Popular Gripper

OnRobot’s popular two-fingered gripper has now doubled its payload capacity with the newly launched 2FG14. This doubles the payload and gripping force of OnRobot’s popular 2FG7 gripper while also providing 30% more total stroke. The 2FG14 is a lightweight parallel finger gripper with a payload of 30.8 lb.

The gripper is ideal in CNC machine tending applications that involve handling heavy metal workpieces with a new base design for challenging work environments where workpieces are frequently exposed to oils or cutting fluids. “The 2FG14 is a great gripper. It’s easy to use and allows our cobots to maintain maximum payload,” said Alex Pinkerton, mechanical engineer at Gosiger, a leading robotics integration firm. “OnRobot products have intuitive, operator-friendly user interfaces and the 2FG14 maintains this tradition. It’s perfect for demanding packaging, machine tending, and assembly applications.”

Ellison Technologies’ AutoPilot powered by D:PLOY

OnRobot has collaborated with provider of advanced machining solutions, Ellison Technologies, on the new AutoPilot powered by D:PLOY. This simplifies the process of deploying and redeploying CNC machine tending applications. OnRobot’s D:PLOY is an automated platform for building, running, monitoring, and redeploying collaborative applications. D:PLOY automates the deployment process, which was designed to slash deployment times and enable deployments to take place on the factory floor with zero programming and zero simulations required.

“Companies racing to plug labor gaps and meet growing demand in an uncertain economic climate can’t afford to spend weeks deploying and redeploying CNC machine tending automation,” said Greg Haley, VP of automation at Ellison Technologies. “D:PLOY is the perfect software for Ellison’s AutoPilot solution as it decreases the programming complexity and makes part changeover a snap. This puts automated CNC machine tending in reach for more customers than ever, even those with high mix, low volume part runs.”

Read more about:

Supplier NewsAbout the Author(s)

You May Also Like